What are frequency converters and why are they essential?

With intelligent control of the fan’s electric motor, we ensure optimal electric motor performance.

Frequency converters, also known as variable speed drives (VSDs), are present in our daily lives more often than we realize. We are surrounded by them every day—for instance, when we ride a lift, swim in a pool, or eat at a restaurant.

These devices regulate the output frequency and voltage so that the electricity supplied to the motor is adapted to the real-time demand of the application. This allows the motor's energy consumption to be reduced by 40 to 50%.

Intelligent motor control offers many operational and environmental advantages. The use of frequency converters improves productivity, increases energy efficiency, and extends the service life of equipment. As a result, proper management of electrical consumption leads directly to cost savings.

Depending on the application, there are several types and models of frequency converters. The first parameter to consider is the input and output voltage, which can be single-phase or three-phase. At Morgui Clima, we keep stock of both types:

- 220 V Single-Phase – 220 V Single-Phase

- 220 V Single-Phase – 220 V Three-Phase

- 220 V Three-Phase – 220 V Three-Phase

- 380 V Three-Phase – 380 V Three-Phase

Another key factor in selecting the right frequency converter is the motor power (kW) and the protection rating (IP).

All-resistant regulation and control

In terms of protection, it is worth highlighting the Invertek drives—compact and robust units made in the UK—classified with IP20 or IP66/NEMA 4X protection. IP66/NEMA 4X-rated drives can be used in environments with high levels of dust, moisture, or chemical exposure. They are the ideal choice for applications such as conveyors, mixers, packaging systems, ventilation and fans, and water or liquid pumping systems.

Thanks to their high IP protection and sealing, these drives can be installed close to the extractor, without the need for a protective cabinet—even when exposed to adverse weather or intensive cleaning routines. This makes them a perfect solution for outdoor installations, retrofit projects, and equipment that requires frequent washing. A coated heat sink, a sealed housing, and a dirt-repelling design allow these drives to withstand high-pressure water jets, making them suitable for applications with strict hygiene standards.

In the hospitality sector, frequency converters are especially useful for regulating the motors of smoke extraction ventilation units. With intelligent control of the fan’s electric motor, we ensure optimal air extraction performance.

Optidrive converters are renowned for their easy installation and use. They can be controlled remotely using digital or analogue potentiometers. Their IP20 or IP66 protection makes them ideal for handling by kitchen staff, resistant to dirt, and safe for high-pressure cleaning—ensuring the highest hygiene standards in professional kitchens.

The crucial role of frequency converters in energy saving

The role of variable frequency drives in reducing energy consumption is vital. With the global economy expected to more than double by 2050, it is essential to balance economic growth with reduced energy consumption and lower carbon emissions. According to the IEA (International Energy Agency), 70% of industrial electricity and 38% of electricity in buildings is consumed by electric motors. These two sectors are therefore key targets for reducing energy usage through variable speed drives.

Optidrive frequency converters help adapt motor speeds to the exact requirements of each application, saving energy and providing better control.

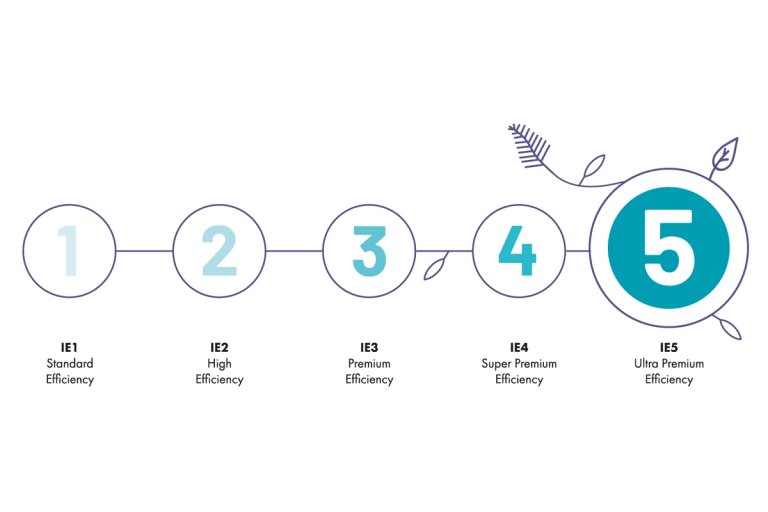

Around the world, governments have introduced energy-saving targets and are implementing laws and regulations to ensure compliance. At the heart of these regulations are the International Efficiency (IE) Standards, designed to promote higher energy efficiency and reduce the consumption of low-voltage AC motors. Even though upgrading to a more efficient motor delivers significant energy savings, even greater savings can be achieved when paired with a frequency converter.

Applicable European regulations

The International Efficiency (IE) standards define the energy efficiency levels for low-voltage AC motors. All Invertek frequency converters are built to exceed the IE2 requirements set by the Ecodesign Directive.

The European Union’s (EU) Ecodesign Directive establishes consistent EU-wide rules to improve the environmental performance of products—from household appliances to engineering equipment. The goal is to avoid 40 million tonnes of CO₂ emissions by 2030.

The latest Ecodesign Regulation (EU) 2019/1781 came into effect in October 2019 and now includes variable frequency drives (VFDs) along with a wider range of motors. A second phase, which expands the scope of the regulation and increases the requirements for motors, will commence on 1st July 2023.

By incorporating regulation and control with frequency converters, we can create more efficient and cost-effective installations—in other words, more sustainable ones.